Your Partner in

High-Quality Solutions

High Precision Machining

We start with engineering customer design, working with them to co-design the components. Based on the agreed final requirements, engineers create a detailed 3D containing dimensions, tolerances, features, scales, and other information.

CAM system software generates the instructions for tool movement based on the CAD model, (CNC programming; the codes are readable by CNC precision machines).

The machine establishes connections with the control system to process the instructions for operation, executing the instructions, and the tools move to perform the machining of the workpiece. Meanwhile, testing for fine-tuning parameters can help produce the parts according to precision requirements.

Materials:

-

Aluminum: 6061T6 / 6082T6 / 6063 T5

-

Steel: SAE 1018 /1045 / 12L14 / 1215

-

Steel: SAE 6061 / 4140 / 8620 /8620H

-

SS: AISI 304 / 316L

-

Tube: E235+C

CNC Turning & Lathes

A CNC lathe rotates the workpiece while a tool moves along it, shaping cylindrical or axially symmetrical items with precision. This method is ideal for manufacturing high-quality, cylindrical components with tight tolerances.

CNC Milling Machines

A rotating cutting tool moves along multiple axes, allowing precise shaping of complex parts. The spindle can rotate up to 8000 rpm, enabling high-speed operations while maintaining accuracy, ideal for plane or flat workpieces.

Cylindrical Grinding

A rotating grinding wheel shapes cylindrical surfaces like rods or crankshafts. The workpiece rotates in the opposite direction, achieving high precision and smooth finishes. This method is used for items with a central axis of rotation.

Plane Grinding

Plane grinding flattens workpieces using a rotating grinding wheel. The process ensures precise thickness or surface roughness, with a coolant applied to reduce heat. It’s commonly used to achieve even, flat surfaces on materials.

Aluminum Extruded Profile

The method of CNC aluminum extrusion involves pushing molten material through a die’s opening to create an extended component with a continuous profile. Although CNC aluminum extrusion is a useful process for creating functional parts with high-quality surface finishes and intricate cross-sections, its use is restricted since the cross-sections must be uniform throughout the item.

The pieces produced by the extrusion of aluminum can be post-machined with cutting and CNC milling process

Materials:

-

6061 / 6082 / 6005 / 6351 /6063 / 6060

Cutting

We have a capability for cutting aluminum profiles

Max capacity:

Max Width

Max Height

Max Round

Max Square

Max Rectangular

450 mm

220 mm

200 mm

200x200 mm

350x130 mm

Max capacity:

Max Width

Max Height

Max Round

Max Square

Max Rectangular

Solid Round

Solid Square

270 mm

125 mm

125 mm

100x100 mm

140x60 mm

90 mm

80x80 mm

Milling

We have the capability for 3 & 4 axes for high productivity

Travel:

X-axis

Y-axis

Z-axis

Spindle

nose to table

711 mm

406 mm

394 mm

546-152 mm

Travel:

X-axis

Y-axis

Z-axis

Spindle

nose to table

650 mm

400 mm

305 mm

250-555 mm

Cold Forging

Cold forming is a high-speed forging process where a coiled wire is sheared and shaped through the tool and die cavities at room temperature, altering its size or shape without exceeding its tensile strength.

We use horizontal transfer molding machines and custom-designed equipment for precise, complex components. Induction pre-heating is employed for enhanced quality and production efficiency in geometrically complex parts.

Materials:

-

Carbon steels

-

Aluminum

-

Brass

-

Bronze

-

Lead

-

Copper

-

Aerospace Alloys

-

Alloy steels

-

Nickel Alloys

Benefits of cold forging

-

Speed

-

Net / Near net shape to eliminate or reduce secondary operations

-

Consistency / dimensional accuracy

-

Quality / surface finish

-

Material savings & elimination of scrap

-

Improvement in mechanical properties, greater strength-to-weight ratio, unbroken grain flow

Because of these benefits, Cold forming can be considered instead of Hot Forging, Casting, Powdered Metal, Machined Parts, Weldments and Stampings, or Reinforced Plastics / Composites.

Some of our products

Inflator Airbag

Powertrain anti-vibration systems

Car Interior

components

Busings

Hydraulic Components

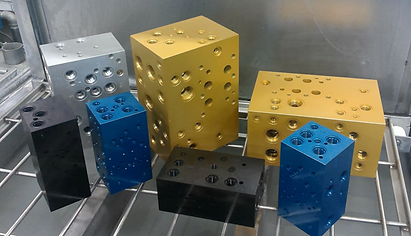

Today, the company offers custom design and manufacturing services for hydraulic and pneumatic manifolds made of ductile iron, aluminum, stainless steel, and brass. We can produce manifolds that require systems with unique fluid power under customer design.

Materials:

Magnum Fluid offers a wide range of material choices to meet most pressure rating, application, environment, and cost requirements. While the vast majority of products that we build have criteria that are best served by 6061-T6511 aluminum or 65-45-12 ductile iron, we also frequently review requests for custom products in other grades of aluminum and ductile iron. This includes stainless steel, carbon steel, and other advanced materials.

Alluminum

-

6061-T651: Used in our entire aluminum standard product line and 99% of our custom aluminum products. Items built from the extruded bar are -T6511 temper and items built from the plate are –T651 temper.

-

2024-T351: Used for some custom parts when specified. Usually, it is chosen over 6061 when improved material strength is needed. The majority of what we purchase is plate.

-

7075-T351: Used for some custom parts when specified. Typically, it is decided over 6061 when improved material strength is needed. The majority of what we purchase is plate.

Ductile

-

65-45-12: Used in our entire ductile standard product line and nearly all of our custom ductile products.

-

80-55-06: Used for a very small number of custom parts. Usually, it is chosen over 65-45-12 when improved material strength is needed.

Some of our products